INJECTION MOLDINg Services

Cove Plastics is a Polymer Components division specializing in injection molding, located in Dayton, Tennessee, and dedicated to serving our injection molding customers. With over 100 years of combined experience, we've tackled almost every kind of injection molding job imaginable. With our experience, we'll keep your job on time and on budget.

Two-for-One

Since Cove Plastics is backed by Polymer Components we have a diverse knowledge of materials and can seamlessly transition you from Cast to Injection or back, giving you the freedom to maneuver.

Material Choice

We have a wide range of materials for injection molding. TPU / TPR, silicon, ABS, and many more. Visit our materials page for more information.

Machining

Cove Plastics utilizes a full, state-of-the-art machine shop. This allows us to provide any inserts needed and also hold any tight tolerances needed.

Tennessee Based Injection Molder

How Our Injection Molding Can Help Your Business

-

Low Piece Price

-

Fast Turnarounds

-

Extremely High Quailty

-

Small to Large Parts

-

Wide Material Selection

-

Mold Making / Design

-

ABS (Acrylon Butadiene Styrene)

-

Acetal (Polyoxymethylene or POM)

-

HDPE (High-density Polyethylene)

-

Nylon (Standard & Glass Filled aka PA)

-

PC (Polycarbonate)

-

PBT (Polybutylene terephthalate)

-

PET (Polyethylene Terephthalate)

Materials

Polymer Components prides itself on versatility. We excel at injection molding with dozens of materials and material variations. Here is a sample list of some of the materials we frequently use

-

PS (Polystyrene) *Solid Variation Only

-

PP (Polypropylene)

-

PPE (Polyphenylene Ether)

-

TPE (Thermoplastic Elastomer aka TPR)

-

TPO (Thermoplastic Polyolefin)

-

TPU (Thermoplastic Polyurethane)

-

SAN (Styrene-acrylonitrile resin)

capabilities

Cove Plastics has nearly two dozen injection machines spread across two locations. Our injection machines can accommodate up to 80-ounce (2270 g) shots and our clamping pressures run as high as 550 tons. With our vast machine variation and inventory, Polymer Components can accommodate low or high-volume runs and in dozens of materials.

Already have a mold? Great, we can use your existing molds in our system and save you money. Our tie bar spacing sizes range from 14" x14" (355.6mm x 355.6mm) to 33" x 31" (838.2mm x 787.4mm). For anything larger please call and ask for more information.

Don't have a mold? No problem, along with our state-of-the-art molding facility, we boast an equally robust machine shop. From mold design to production, Polymer Components can help every step of the way in creating an injection mold for your company.

Related Product

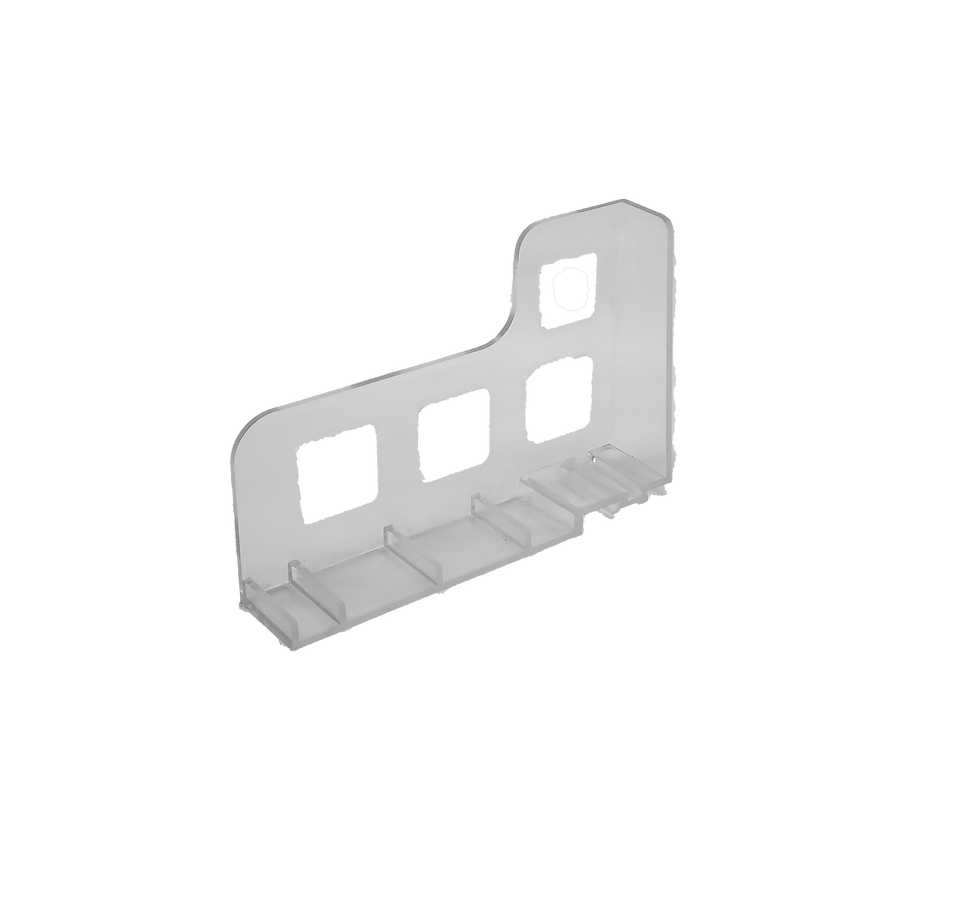

Clear ABS dividers

Glass Filled Nylon Clip